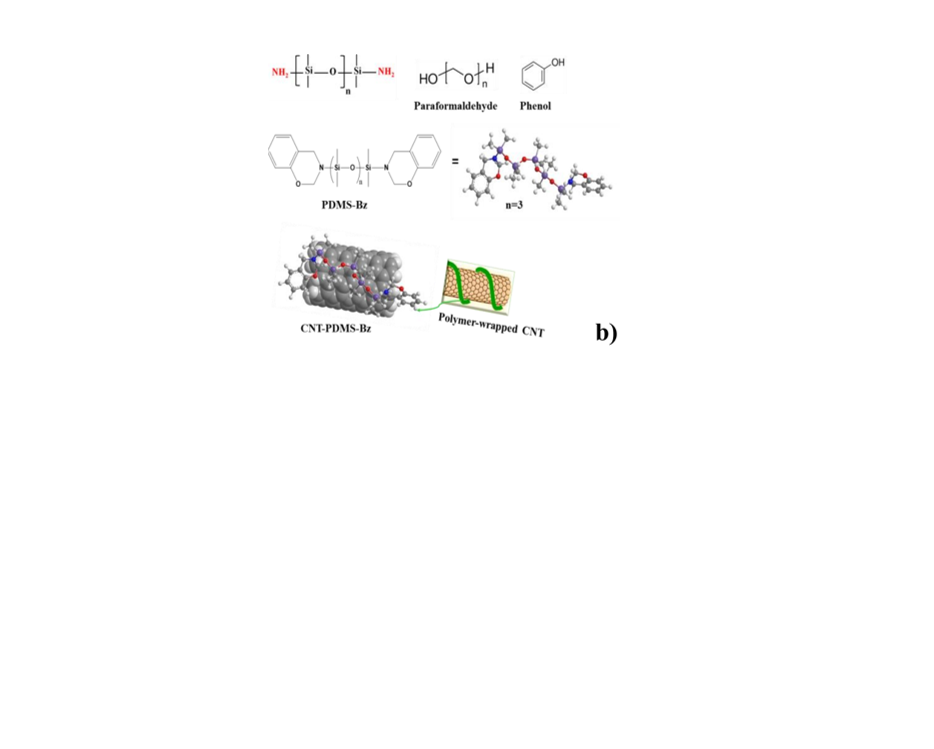

Multifunctionality of structural nanohybrids: the crucial role of carbon nanotube covalent and non-covalent functionalization in enabling high thermal, mechanical and self-healing performance

Multifunctionality of structural nanohybrids: the crucial role of carbon nanotube covalent and non-covalent functionalization in enabling high thermal, mechanical and self-healing performance Raimondo, M., Naddeo, C., Vertuccio, L., Bonnaud L., Dubois, Ph., Binder, W.H., Sorrentino, A., Guadagno, L. Abstract : This study proposes new kinds of functionalization procedures able to preserve specific properties of carbon nanotubes […]

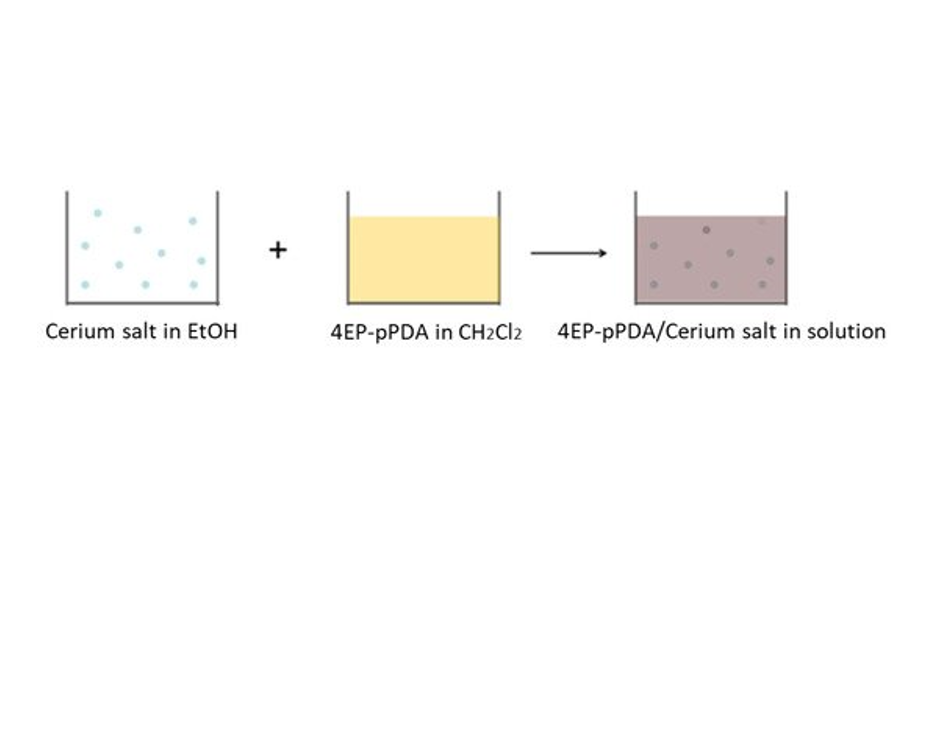

Cerium Salts: An Efficient Curing Catalyst for Benzoxazine Based Coatings

Cerium Salts: An Efficient Curing Catalyst for Benzoxazine Based Coatings Tao Zhang, Leila Bonnaud, Jean-Marie Racquez, Marc Poorteman, Marjorie Olivier and Philippe Dubois Abstract : The effect of three different cerium salts (Ce(NO3)3·6H2O, CeCl3·7H2O and Ce(OOCCH3)3·5H2O) on the ring-opening polymerization (ROP) of a model diamine-based benzoxazine (4EP-pPDA) was investigated. With the incorporation of the cerium […]

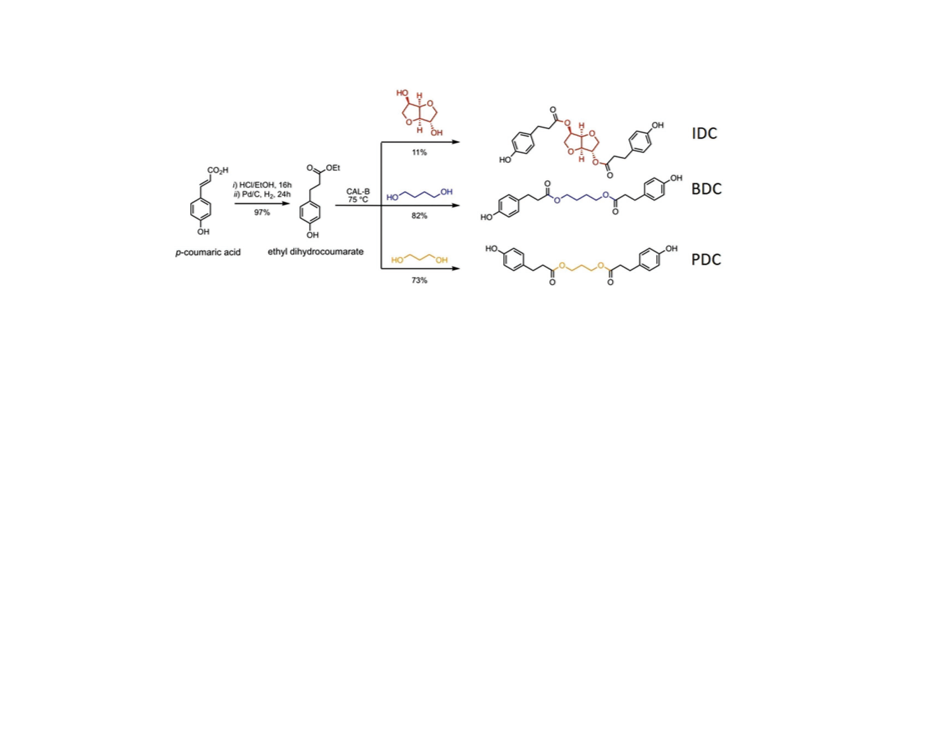

High‐Performance Bio‐Based Benzoxazines from Enzymatic Synthesis of Diphenols

High‐Performance Bio‐Based Benzoxazines from Enzymatic Synthesis of Diphenols Leïla Bonnaud, Benjamin Chollet, Ludovic Dumas, Aurélien A. M. Peru, Amandine L. Flourat, Florent Allais, and Philippe Dubois Abstract : This paper reports the preparation, characterization, and performance of three low viscosity fully bio‐based benzoxazine resins synthesized from bio‐based furfurylamine, paraformaldehyde, and three new enzymatic originated diphenols […]

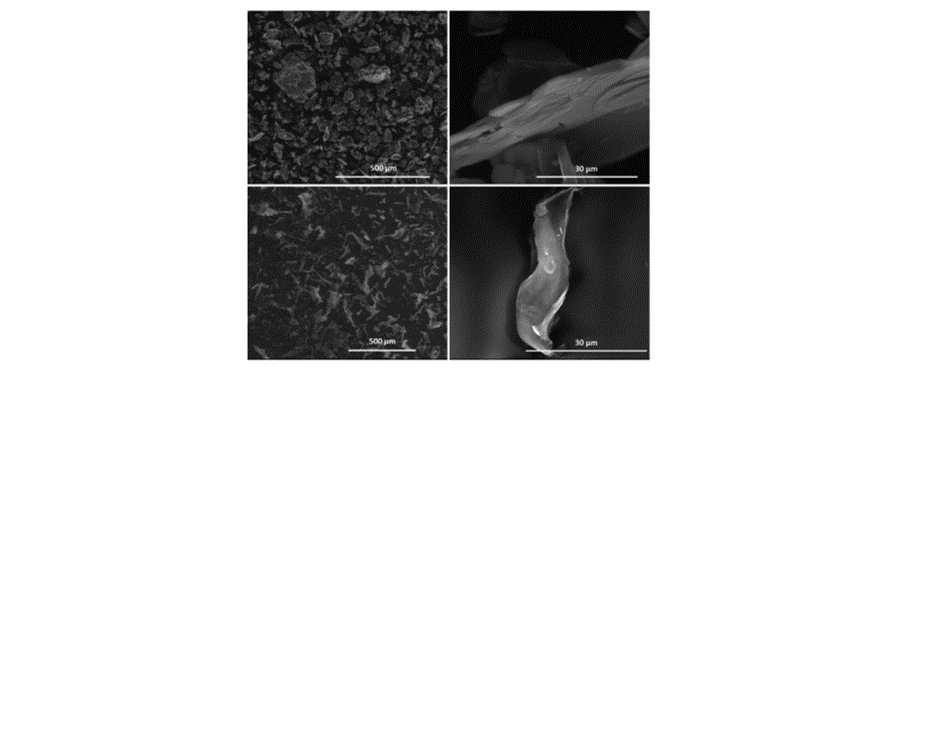

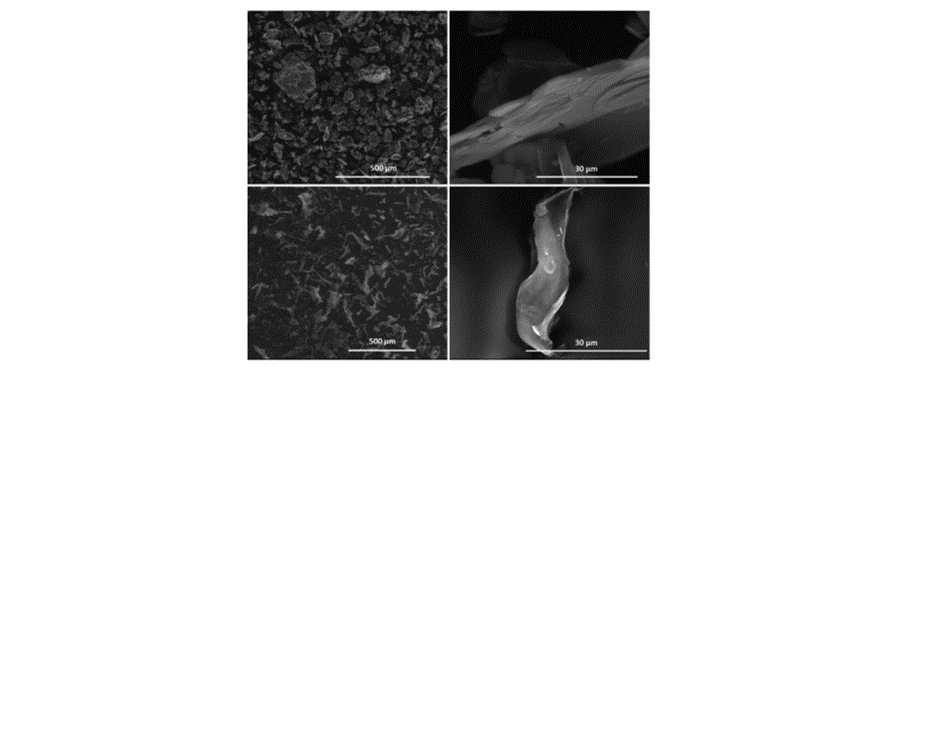

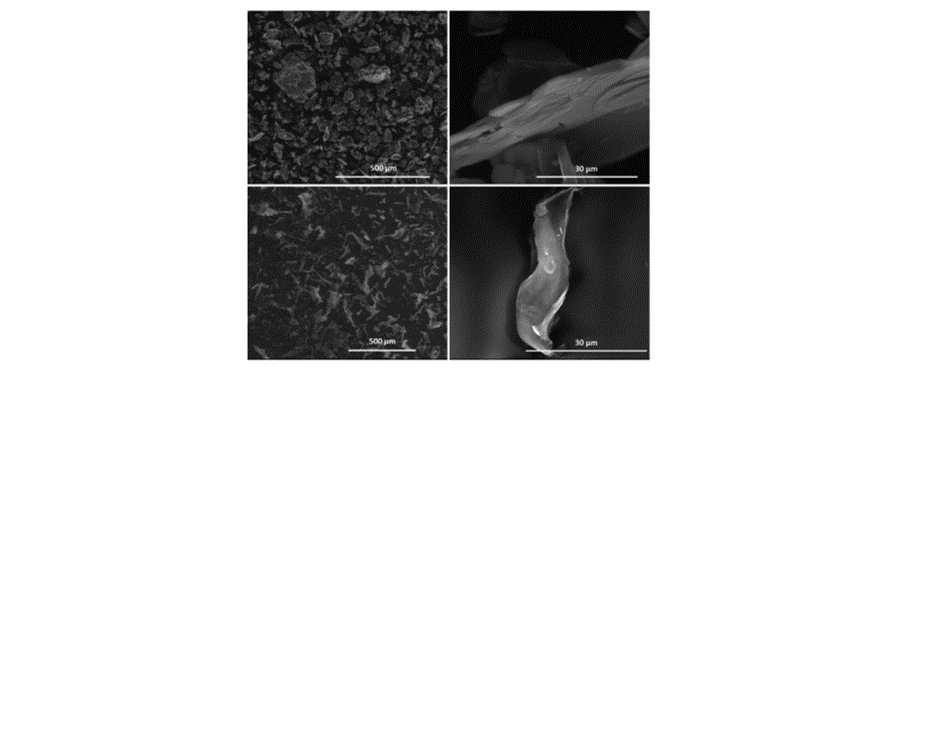

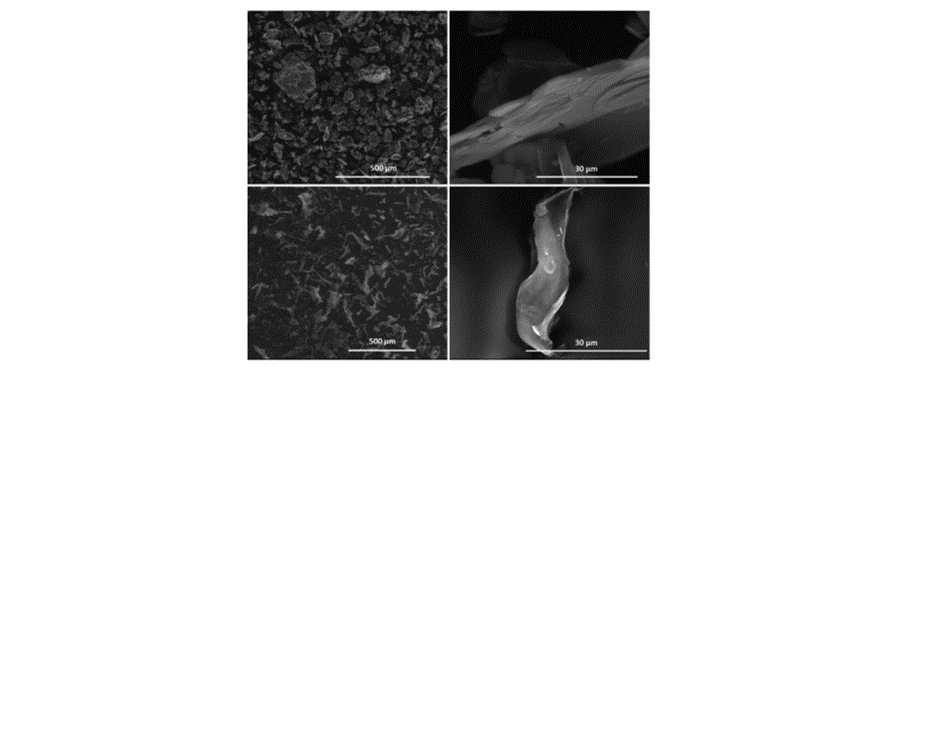

Enhancement of thermal conductivity in epoxy coatings through the combined addition of expanded graphite and boron nitride fillers

Enhancement of thermal conductivity in epoxy coatings through the combined addition of expanded graphite and boron nitride fillers Isaac Isarn, Leïla Bonnaud, Lluís Massagués, Àngels Serra, Francesc Ferrando Abstract : Expanded graphite (EG) and boron nitride (BN) were used as fillers to impart thermal conductivity (TC) while maintaining electrical insulation of a homopolymerized cycloaliphatic epoxy […]

Enhancement of thermal conductivity in epoxy coatings through the combined addition of expanded graphite and boron nitride fillers

Enhancement of thermal conductivity in epoxy coatings through the combined addition of expanded graphite and boron nitride fillers Isaac Isarn, Leïla Bonnaud, Lluís Massagués, Àngels Serra, Francesc Ferrando Abstract : Expanded graphite (EG) and boron nitride (BN) were used as fillers to impart thermal conductivity (TC) while maintaining electrical insulation of a homopolymerized cycloaliphatic epoxy […]

A benzoxazine/substituted borazine composite coating: A new resin for improving the corrosion resistance of the pristine benzoxazine coating applied on aluminum

A benzoxazine/substituted borazine composite coating: A new resin for improving the corrosion resistance of the pristine benzoxazine coating applied on aluminum Alexis Renaud, Leïla Bonnaud, Ludovic Dumas, Tao Zhang, Yoann Paint, Francesco Fasano, Olesia Kulyk, Eva Pospisilova, Bernard Nysten, Arnaud Delcorte, Davide Bonifazi, Philippe Dubois, Marie-Georges Olivier, Marc Poorteman Abstract : In this paper, laboratory synthesized […]